Rapid prototyping has totally transformed how we develop products, turning fresh ideas into hands-on experiences faster than ever.

Every year, around 30,000 new products hit the market. In this busy scene, being able to quickly test and improve your ideas is what sets you aside from other manufacturers. Rapid prototyping helps by quickly turning design ideas into real, touchable models. This way, you can see and feel how a product works much sooner, sometimes in just a few hours instead of weeks.

This fast pace means companies can keep up with quick changes in the market and get their products out there faster. By creating real-life versions of products early in the design process, you can spot problems and get feedback before making lots of them. This ability to make changes quickly and often gives you a real advantage, especially when so many new products are competing for attention every year.

In this article, we’ll focus on how using rapid prototyping can help your projects succeed faster and better, helping you stay ahead in the busy market.

Accelerates Product Development

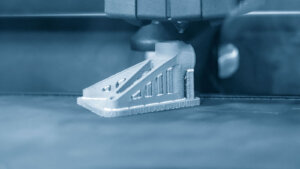

Rapid prototyping dramatically accelerates the product development cycle, enabling prototypes to be produced in under a week, and sometimes in just a few hours. This rapid turnaround allows teams to test and iterate multiple concepts much faster than traditional methods, effectively improving time-to-market. For instance, simple 3D printed parts smaller than 4 inches can be ready in about four hours, showcasing the method’s efficiency.

By integrating automated testing capabilities and instant production directly from computer-aided design (CAD) data, workflows are further streamlined, allowing for immediate validations.

Reduces Costs

Prototypes that might cost less than $100 starkly contrast with traditional methods that are much more expensive. This cost efficiency extends beyond just production — by identifying design flaws early through rapid prototyping, companies prevent costly post-production changes, thus avoiding substantial financial losses.

Traditional methods generally require high upfront investments for custom tooling, but the digital nature of rapid prototyping minimizes these expenditures. Equipment costs do vary; while small desktop 3D printers might be highly affordable, professional-grade machines could cost between $5,000 to $15,000.

Supports Iterative Testing

Iterative testing facilitated by rapid prototyping allows for the quick production and evaluation of multiple design versions, saving both time and money. This process not only identifies and rectifies flaws swiftly but also enhances the quality of the end products through successive refinements. Rapid prototyping supports the use of automated validation tools that simulate various conditions to predict mechanical behaviors and material performance.

The frequent iteration made possible by rapid prototyping aligns products more closely with user expectations, thereby enhancing the user experience. It mitigates risks associated with late-stage design overhauls and ensures that the final product benefits from well-informed, successive improvements.

Improves Communication and Collaboration

Physical prototypes serve as effective communication tools, making it easier for designers, engineers, and stakeholders to understand design concepts and provide high-quality feedback. This clarity is invaluable in complex development environments where technical and non-technical team members must collaborate closely.

These tangible models aid in reducing misunderstandings and foster effective brainstorming sessions, even with remote or cross-functional teams. The ability to physically examine prototypes helps in making prompt, informed decisions, streamlining the approval process, and ensuring swift implementation of necessary adjustments.

Ease Customization and Personalization

Rapid prototyping allows for rapid testing of various features, enabling adjustments to product dimensions, material properties, and aesthetics efficiently and cost-effectively.

The quick turnaround of rapid prototyping processes means companies can respond swiftly to unique consumer requests, opening up new opportunities in consumer-driven markets. Digital files used in prototyping can be easily modified to cater to different user groups, thereby facilitating entry into high-value niche markets and ensuring products meet precise customer expectations.

Helps with Design Validation and Functionality Testing

Rapid prototyping enhances design validation and functionality testing by allowing product teams to verify the form, fit, and performance of prototypes early in the development cycle. This process significantly reduces the likelihood of product failure after launch as products undergo rigorous testing against usability, ergonomics, and environmental conditions. For example, materials like Nylon 12, which withstands temperatures up to 300°F (149°C), can be evaluated for high-temperature applications.

Moreover, rapid prototyping facilitates the testing of mechanical properties and load-bearing capabilities, often supported by advanced software simulations.

Mitigates Risks and Issues

By creating early prototypes, companies can prevent expensive, late-stage redesigns and reduce the risk of recalls or returns. The early detection of flaws through rapid prototyping not only saves financial resources but also helps in preserving the brand reputation.

This proactive approach allows for the validation of design concepts before committing to expensive tooling and production processes, significantly lowering the uncertainty surrounding new product developments.

Supports Innovation and Creativity

Rapid prototyping encourages experimentation with complex geometries and intricate designs that may be impossible to achieve through traditional manufacturing methods. It allows designers to consolidate multiple parts into a single, more efficient prototype, thus exploring innovative solutions that can lead to breakthrough products that redefine industry norms.

The ability to quickly iterate designs frees designers from the conventional constraints of manufacturing, enabling the creation of unique structural forms and user-focused features.

Enhances Product Quality

Rapid prototyping significantly enhances the quality of products by allowing multiple rounds of testing, which improve the product’s durability, usability, and aesthetics. High-quality prototypes that closely match the final product specifications are instrumental in ensuring that the end products are reliable and meet all user requirements.

The early discovery and correction of design flaws facilitate the creation of superior products, which in turn leads to greater customer satisfaction and fewer after-sales service issues and warranty claims.

Improves Design Flexibility

Rapid prototyping significantly enhances design flexibility, allowing product teams to make quick adjustments to design elements at any stage without the need for major retooling. This flexibility is ideal for exploring various materials and structural variations, enabling teams to test multiple options to identify the best solution efficiently. The adaptability in materials, ranging from standard plastics to high-performance polymers, expands the design possibilities immensely. This flexibility not only supports continuous improvement but also adapts seamlessly even if project requirements evolve during the development process, ensuring that the final product can meet the dynamic needs of the market.

Market Testing and Validation

This early testing phase helps confirm market demand and aligns the product more closely with consumer needs. By producing realistic prototypes, teams can conduct user trials, focus groups, and surveys to ensure the product resonates well with its intended audience. Early input from these sessions significantly reduces the risk of launching a product that does not meet market expectations, thereby saving resources and safeguarding the brand image. Moreover, thorough market validation through rapid prototyping enhances investor confidence and can facilitate funding efforts, further supporting the product’s success.

Increase Scalability

100vw, 800px” data-lazy-src=”https://www.3erp.com/wp-content/uploads/2020/07/5-min-300×169.jpg” /></p>

<p>Rapid prototyping facilitates the smooth transition from one-off prototypes to small batch productions, making scalability more manageable. As market demand increases, the iterative approach of rapid prototyping allows companies to fine-tune manufacturing parameters before committing to mass production. This scalability ensures that companies can respond efficiently to changing market conditions and capitalize on emerging trends without significant disruptions. Moreover, the ability to scale from prototype to full production seamlessly helps maintain steady supply chains and minimizes the risks associated with scaling up production.</p>

<h2 id=) Improves Sustainability

Improves Sustainability

Rapid prototyping contributes significantly to sustainability in manufacturing. By using only the materials needed, layer by layer, this method reduces material wastage and encourages more eco-friendly practices throughout the production process. Some advanced prototyping methods can reduce post-processing requirements by up to 90%, further minimizing resource use. Although rapid prototyping is generally more resource-efficient, it is crucial to consider the energy consumption and recyclability of the processes and materials used.

Allow Exploration of Different Material Properties

Rapid prototyping allows teams to test how different materials, such as plastics, metals, and resins, handle specific temperatures, stresses, or environmental conditions. Rapid prototyping technologies support a broad range of materials from common thermoplastics like ABS, PLA, Nylon, and PETG to high-performance polymers like Ultem. This diversity enables designers to pinpoint the ideal materials for structural integrity, heat resistance, chemical resilience, or aesthetic finishes. Exploring these material options during the prototype phase helps avoid the selection of suboptimal materials that could lead to failures in production, ensuring a more successful final product.

Enhance Stakeholder Involvement

This early involvement helps quickly resolve misunderstandings and aligns everyone’s vision, enhancing the collaborative process. Physical prototypes allow direct feedback from clients, suppliers, investors, and even regulators, which improves trust and transparency throughout the project lifecycle. Presenting stakeholders with a working model not only encourages more meaningful discussions but also accelerates consensus-building. This increased engagement can lead to early investor backing when prototypes demonstrate the feasibility of the concept and its market potential.

Provides Competitive Advantage

Rapid prototyping offers a significant competitive advantage by enabling faster product launches and better-quality outputs, which are crucial in a crowded marketplace. By rapidly adapting to consumer demands and continuously improving product quality and user experience, companies using rapid prototyping can strengthen their brand position. This method allows businesses to swiftly capitalize on new trends and customer preferences, gaining a foothold in the market before competitors. Moreover, rapid prototyping supports innovation pipelines, ensuring a steady flow of refreshed offerings that maintain competitiveness and foster long-term brand loyalty.

Supports Low-Volume Production

Rapid prototyping is ideal for supporting low-volume production, which is essential for testing markets or fulfilling initial orders before a full-scale production commitment. This approach allows companies to validate product-market fit with minimal inventory risk. Producing limited batches helps gauge real-world demand without the need for extensive resources, reducing storage costs and waste if market response is less than anticipated. Low-volume production is particularly beneficial for niche markets or custom orders, where the demand may not initially justify high-volume production, allowing for a more tailored approach to market entry and product success.

Support Training and Demonstrations

Rapid prototyping significantly enhances the efficacy of training sessions and demonstrations by providing physical models that reflect the final product. These tangible prototypes help trainers and technicians offer realistic demonstrations, considerably speeding up the learning curve for new team members. Additionally, marketing and sales teams utilize these models in presentations and exhibitions, significantly enhancing product visibility and comprehension. This direct interaction with prototypes allows teams and customers to better understand product usage, thereby reducing misuse, maintenance issues, and overall lifecycle costs, as informed users are less likely to mishandle the product.

Improve Communication Across Teams

Utilizing physical prototypes within product development serves as a universal language that bridges gaps between cross-functional teams. This visual and tactile form of communication improves clarity and reduces misunderstandings, allowing teams including engineers, designers, procurement specialists, and management to stay aligned on the project goals. The shared reference helps minimize errors arising from misinterpretations of complex plans, ensuring all departments work towards unified project milestones efficiently.

Encourage the Usage of Advanced Manufacturing Techniques

Rapid prototyping pushes the boundaries of manufacturing by encouraging the adoption of advanced techniques like additive manufacturing, direct laser sintering (DLS), and other cutting-edge methods. These technologies allow for the exploration of complex geometries and unique design features that are often too costly or impossible with traditional tooling. Processes such as stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM) provide a diverse range of resolutions, material choices, and mechanical properties, catering to varied design requirements. Early use of these techniques ensures the selection of the most suitable production process, enhancing both efficiency and cost-effectiveness as projects scale from prototypes to full production.

Speed Up Error Identification and Correction

The iterative nature of rapid prototyping accelerates the identification and correction of design flaws, ergonomic issues, or safety hazards, dramatically reducing downtime and resource wastage. By facilitating multiple quick feedback loops during the prototyping phase, teams can refine the design incrementally, ensuring the product is optimized before mass production begins. This agility in development not only cuts down on expensive post-launch troubleshooting but also builds consumer trust as the final products are thoroughly vetted and refined.

Improve Workflow Efficiency

Rapid prototyping streamlines the design-to-production cycle significantly, reducing bottlenecks that traditionally slow development. By integrating digital workflows and automating builds, the need for manual intervention is minimized, which slashes lead times dramatically. This improvement in efficiency not only frees up resources to focus more on refining products and exploring new opportunities but also helps maintain predictable schedules and stable supply chains. The smoother workflow fosters an environment where teams can innovate without the constant pressure of delays, ensuring a seamless transition from concept to market-ready product.

Reduce Development Time for Complex Projects

Complex projects particularly benefit from the accelerated design validation phases provided by rapid prototyping. This technology enables rapid iteration, which drives the completion of complex assemblies much faster than traditional methods. Intricate designs or multi-component products are tested at each layer of complexity, which greatly improves integration and functionality. Rapid prototyping also allows for parallel testing of various modules, significantly speeding up the overall project timeline and providing early insights into manufacturing feasibility, thereby lowering long-term risks associated with complex product development.

Support Agile Development Processes

Rapid prototyping aligns perfectly with agile methodologies, which prioritize quick feedback loops and continuous iteration. This compatibility encourages continuous improvement and rapid adaptation within product design processes. The iterative nature of rapid prototyping meshes seamlessly with agile sprints and regular stakeholder reviews, providing tangible deliverables at each iteration that enhance transparency and accountability. Such approaches minimize development uncertainty and enable teams to adapt quickly to evolving market demands, ultimately delivering better products faster.

Provide Better Visualization of End Products

Enhanced visualization of end products is a significant advantage of rapid prototyping. Physical models help stakeholders appreciate the scale, aesthetics, and user experience of a product far better than digital representations. Such models reveal tactile qualities and allow designers to assess proportions and ergonomics effectively. This improved visualization reduces guesswork and ensures that the final products align closely with the intended design vision. Additionally, better visualization aids significantly in marketing and user testing, enhancing the overall appeal and likelihood of success in the market.

Speed Up Client and Team Approvals

The use of physical models in rapid prototyping significantly accelerates the decision-making and approval processes within teams and among stakeholders. By providing a tangible model, rapid prototyping minimizes the back-and-forth debates over abstract concepts, allowing stakeholders to give definitive feedback and expedite sign-offs. This process not only maintains project momentum but also minimizes costly delays, ensuring that projects proceed without unnecessary interruptions. Moreover, high-fidelity prototypes reassure clients that their specifications are being met accurately, fostering trust and satisfaction.

Facilitates Multi-Material Prototyping

Rapid prototyping greatly enhances the capability to test multiple materials within a single prototype, supporting the exploration of various combinations to achieve optimal performance. By integrating different materials with varied mechanical and thermal properties into one prototype, engineers can obtain a comprehensive understanding of how different elements interact, which is crucial for ensuring product integrity. This multi-material approach supports innovation in designing complex assemblies, such as testing joints, seals, or flexible components, thereby enhancing the product’s functionality and durability while minimizing trial-and-error in the final production stages.

Improve Supply Chain Communication

Rapid prototyping enhances supply chain communication by providing tangible prototypes that help suppliers understand exact specifications more clearly. This clarity reduces misinterpretations and streamlines the sourcing process, as suppliers can verify fit, tolerances, and compatibility more accurately. Improved alignment through these prototypes not only reduces lead times but also prevents material mismatches and ensures timely deliveries. Furthermore, the increased clarity fosters long-term supplier relationships, enhancing stability and cost-effectiveness across the supply chain.

Encourages Cross-Disciplinary Collaboration

Physical models foster an environment where designers, engineers, and marketers can collaborate more effectively. This interdisciplinary approach not only breaks down silos but also integrates perspectives from different functional areas, leading to more holistic product solutions. Such collaboration typically results in innovative solutions that meet both technical requirements and user preferences, accelerating the refinement of designs and enhancing the relevance and appeal of the final products.

Reduces Barriers to Entry for Innovation

Rapid prototyping significantly lowers the barriers to entry for innovation by reducing costs and accelerating production times. This accessibility allows smaller teams and startups to experiment and iterate on prototypes without substantial capital investments. As a result, more players can enter markets and bring innovative ideas to fruition, enhancing market diversity and consumer choice. This democratization of prototyping fosters a broader spectrum of innovation, potentially accelerating the innovation cycles within industries.

Simplifies Product Modification and Redesign

The agility of rapid prototyping simplifies the process of modifying and redesigning products. Quick adjustments to designs and the production of new prototypes allow for continuous improvement, ensuring that products meet the desired standards before reaching the market. This rapid iteration minimizes downtime and reduces the risk of market failures due to unresolved issues. Additionally, easier and faster redesigns alleviate pressure on development teams, leading to better project outcomes and a final product that aligns closely with consumer expectations and market needs.

Promotes Prototyping in Remote Collaboration Scenarios

Rapid prototyping revolutionizes remote collaboration by allowing distributed teams to share and verify physical samples quickly. Secure digital transfers of CAD files enable global partners to produce identical prototypes locally, bridging geographical gaps. This technology not only shortens feedback loops across different time zones but also boosts the efficiency of international collaborations. For companies managing international supply chains or engaging in global research partnerships, the ability to conduct easy remote prototyping is invaluable.

How Can You Maximize the Benefits of Rapid Prototyping?

To fully leverage the advantages of rapid prototyping, it’s crucial to set clear objectives from the outset. Selecting the right materials and manufacturing techniques that align with the intended functionality of your product is essential. Adopting an iterative approach, where designs are continuously refined based on feedback, is key. Choosing the most appropriate rapid prototyping methods—such as SLS, SLA, FDM, or CNC machining—ensures alignment with your product goals and material requirements. Involving stakeholders and end-users early in the process allows for more targeted feedback and efficient iterations. Additionally, utilizing software simulations and AI-driven optimizations before actual printing can drastically reduce the trial-and-error phase.

What Are the Best Practices to Maximize the Benefits of Rapid Prototyping?

Best practices for maximizing the benefits of rapid prototyping include defining clear objectives and choosing the right tools and materials that mirror the final product’s properties, which minimizes differences at launch. Embracing agile methods allows for quick iterations and ensures that each prototype meets minimum quality standards despite the rapid pace. Early stakeholder feedback prevents prolonged design cycles, and validating initial concepts digitally can reduce the need for numerous physical prototypes. Technologies that minimize time-to-part and reduce post-processing by up to 90% are particularly valuable. Continuous documentation of each iteration’s outcomes informs future refinements and ensures efficient resource allocation by maintaining a detailed record of costs and time for each prototype.

What Are the Disadvantages of Rapid Prototyping?

Rapid prototyping offers transformative benefits for product development, but it also comes with its set of limitations that can affect project outcomes. Understanding these drawbacks is essential for teams to navigate potential pitfalls effectively:

- Limited Material Choices: Some rapid prototyping methods restrict the use of diverse materials, limiting the testing of physical properties.

- Cost Concerns: Technologies like metal 3D printing are still costly, impacting budget constraints for projects.

- Iteration without Clear Goals: Without defined objectives, rapid prototyping can inadvertently extend the product launch timeline due to unfocused iterations.

- High Initial Investments: Although generally cost-effective, the initial cost for purchasing equipment or hiring specialized expertise can be significant.

- Differences in Prototype Quality: Prototypes might not always match the quality or precision of final production parts, particularly in surface finishes and strength.

- Material Limitations: Replicating certain materials, such as wood, cloth, or specific composites, is often challenging with standard prototyping technologies.

- Complex Assemblies Challenges: Large or intricate designs may require the assembly of multiple components, complicating the rapid prototyping process.

- Environmental Impact: The use of non-recyclable materials and high energy consumption in some prototyping methods could raise environmental concerns.

- Risk of Extended Development Cycles: Teams that do not set clear prototyping goals may experience longer development periods, increasing time to market.

Conclusion

Despite having some drawbacks, we cannot argue the importance of rapid prototyping in product development. When you need a product developed faster and seamlessly, while also reducing costs, rapid prototyping is the way to go.

It not only ensures superior product quality but also gives you an edge in competitive markets. That aside, it helps boost your confidence as an investor, because you are certain your customers are receiving the absolute best, and this is why it’s classified as an agile, forward thinking strategy.

By integrating rapid prototyping into your processes, you are not just keeping up—but setting the pace, ensuring projects are resilient, adaptable, and aligned with both market demands and regulatory standards. This isn’t just about staying relevant; it’s about driving continual growth and maintaining a sharp edge in a world that keeps evolving.