You might not think about it, but the world around you runs on parts you can’t even see, tiny components built to exact specs, often thinner than a human hair. That’s what precision manufacturing is all about: making things that work perfectly, even when the margin for error is less than a fraction of an inch.

And it’s not just a niche anymore. Precision manufacturing now makes up around 70% of the global machining market and continues to grow fast, by 12% as of 2024.

That growth says a lot. From aerospace to smartphones to life-saving medical devices, more industries are depending on ultra-accurate production for tight tolerances, zero defects, and flawless fit.

With tolerances as tight as ±0.0001 inches, this kind of manufacturing goes way beyond what traditional methods can handle.

It’s how you avoid the problems that come from tool wear, human error, or poor alignment, and how you make sure every single part just works.

In this article, we’ll focus on how precision manufacturing helps you design smarter, build better, and stay ahead in today’s world.

What Is Precision Manufacturing?

Precision manufacturing is the production of parts and components that must meet very tight tolerance requirements, typically in the range of microns. This discipline emphasizes dimensional accuracy, process repeatability, and minimal human error across various manufacturing applications.

Precision manufacturing is the production of parts and components that must meet very tight tolerance requirements, typically in the range of microns. This discipline emphasizes dimensional accuracy, process repeatability, and minimal human error across various manufacturing applications.

Unlike traditional methods, which may allow for wider variance and rely heavily on manual input, precision manufacturing uses advanced computer programming and automated control systems.

It leverages tools such as CNC machines and CAD/CAM software to execute designs with a high level of consistency, even over large production volumes. These technologies make it possible to maintain tolerances as tight as ±0.0001 inches in turning operations and around ±0.0005 inches in milling.

What makes precision manufacturing stand out is its ability to handle complex geometries and demanding specifications without sacrificing throughput or reliability.

It integrates multiple pathways, including subtractive methods like machining and laser cutting, and additive methods such as 3D printing. These are coordinated through digital systems that monitor every step of the production process.

This level of detail is essential for manufacturing parts used in fields such as aerospace, automotive, electronics, and medical technology.

When you need a component to fit exactly, function flawlessly, and perform under pressure, precision manufacturing delivers the control and capabilities that traditional processes often lack.

Why is Precision Manufacturing Important?

One of the clearest advantages of precision manufacturing is quality. In industries where lives or millions of dollars are at stake, precision manufacturing enables extremely low defect rates.

For instance, some aerospace parts now show fewer than 50 defects per million produced. This level of quality control isn’t possible with traditional techniques that rely heavily on manual intervention and wider tolerances.

Speed is another key factor. When you automate production with technologies like CNC machining, you can reduce turnaround times by 30 to 50 percent. That’s the kind of efficiency that transforms production from a bottleneck into a competitive edge.

Then there’s cost savings over the long term. Even though advanced machines may have a high up-front cost, the reduced waste, minimal rework, and repeatable output often justify the investment.

You’re not just saving money—you’re avoiding the cascading delays caused by errors or inconsistencies.

More importantly, precision manufacturing unlocks innovation. It supports sub-millimeter features in devices like implants and allows for lightweight, high-strength designs in aerospace structures. Without this process, many of today’s most advanced applications would be out of reach.

How Does Precision Manufacturing Work?

The typical sequence begins with a detailed CAD model, where engineers define exact dimensions, geometries, and material requirements. That model is transferred to a CAM system, which converts it into machine-readable tool paths. These paths guide the machines through every cut, drill, or additive pass.

After programming, the material—whether it’s aluminum, titanium, stainless steel, or engineered plastic—is prepared.

It’s mounted on a fixture that ensures stability during machining. The machine then executes the process, whether through subtractive methods like milling or turning, or additive methods like 3D printing. Some setups combine both.

What’s unique is the use of feedback loops. Probes and sensors continuously monitor tool wear, heat distortion, and part alignment.

Adjustments are made mid-operation to maintain tolerances at the micron level. In some systems, digital twins simulate part deformation in real time to adapt paths before the issue even occurs.

After machining, parts go through post-processing steps like deburring, polishing, or coating. Final inspection is critical, often using coordinate measuring machines or laser scanners—to confirm every specification has been met. This closed-loop control ensures repeatability and high yield, even in mass production.

What are the Different Stages of Precision Manufacturing?

Each production run starts with a feasibility review to confirm the part can be manufactured within tolerance limits. This stage, often called Design for Manufacturability, helps identify and fix issues early.

Once the design is approved, engineers generate the CNC program and simulate tool paths for verification. Tooling and fixtures are prepared to stabilize the workpiece during operations.

Here are the main stages in a precision manufacturing workflow:

- Design for Manufacturability (DfM) Review: Evaluates whether the design can be produced with available machines and materials while meeting accuracy targets.

- CAD Modeling and CAM Programming: Translates design specs into code for CNC equipment, factoring in speeds, feeds, and material characteristics.

- Material Selection and Preparation: Chooses the right stock material based on strength, temperature resistance, and machinability.

- Fixturing and Zero-Setting: Sets reference points and secures the part for consistent machining.

- Machining, Printing, or Casting: Executes the operation using CNC machining, additive methods, or casting depending on part type.

- Tool-Wear Monitoring and SPC: Tracks tool degradation and applies statistical process control to maintain quality.

- Post-Processing and Finishing: Includes deburring, heat treatment, or coating to enhance surface quality and function.

- Inspection and Quality Assurance: Uses digital tools for 100% inspection, ensuring every piece meets tolerance requirements.

- Packaging and Traceability Labelling: Adds identifiers for inventory control and regulatory compliance.

What are the Key Processes Used in Precision Manufacturing?

The key processes used in precision manufacturing include CNC machining, metal casting, injection molding, laser cutting, and additive manufacturing.

The key processes used in precision manufacturing include CNC machining, metal casting, injection molding, laser cutting, and additive manufacturing.

CNC machining is the most widely adopted process, offering excellent dimensional control. Metal casting is preferred for high-volume production with complex shapes. Injection molding excels in plastic part replication, especially when surface finish is critical.

Laser cutting provides clean, accurate cuts in metals and polymers, while additive manufacturing enables fast prototyping and intricate internal structures.

Below, we will discuss each one in more details.

CNC Machining

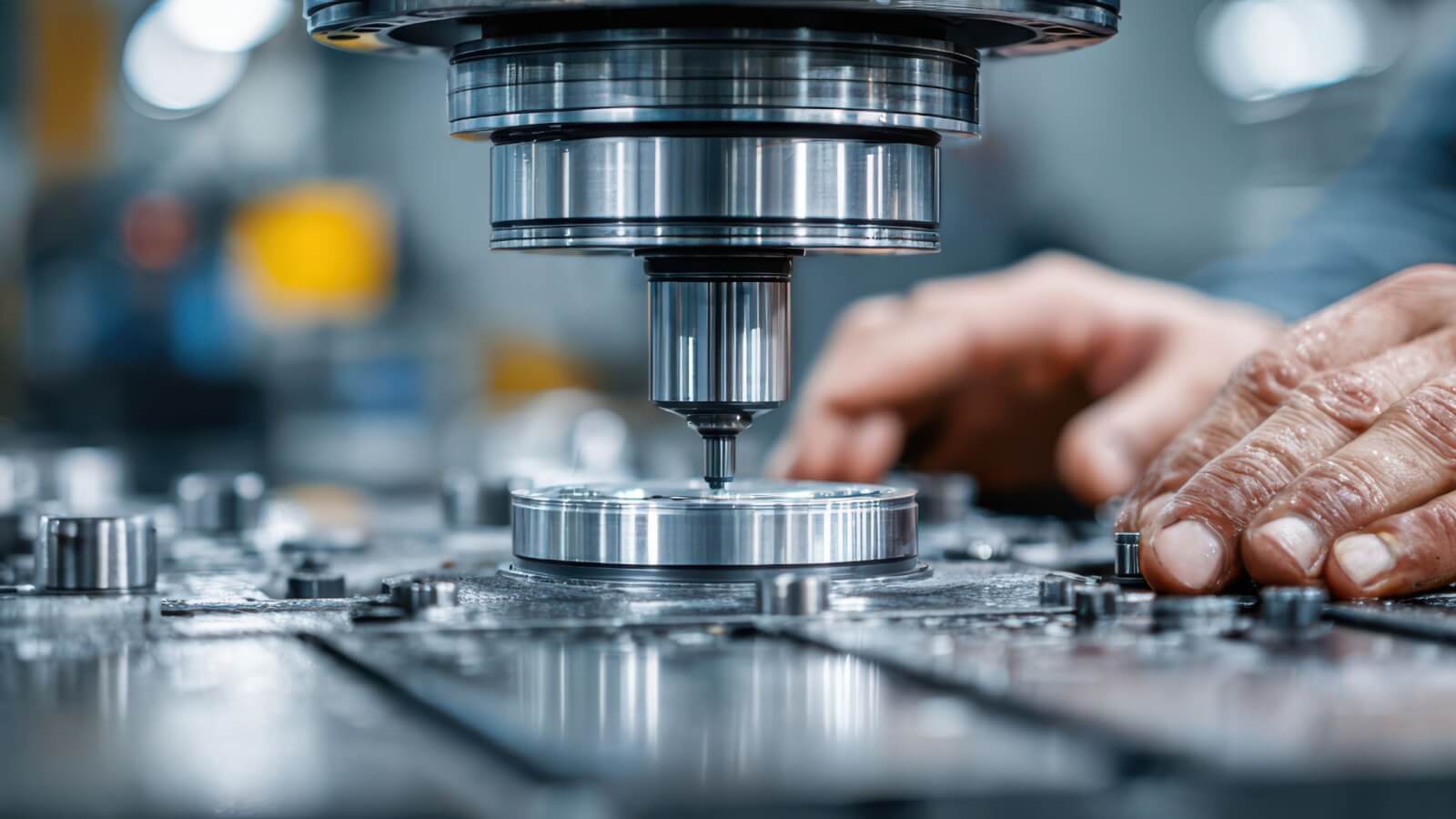

CNC machining technology is a subtractive manufacturing process that uses computer-controlled equipment to shape solid materials into precise parts. The machine reads digital instructions from a CAD/CAM file and executes precise movements along multiple axes to cut, drill, or mill a part.

Because each move is programmed, there is minimal variation between parts, even in large production runs.

This method reduces the chance of human error by automating the entire operation. You can work with a wide range of materials including aluminum, stainless steel, titanium, plastics, and composites.

Five-axis CNC milling systems allow you to machine complex geometries like turbine blades or orthopedic implants in a single setup, reducing fixture time and increasing efficiency.

What sets CNC machining apart is its ability to meet tight tolerances and achieve consistent surface finishes. Typical milling tolerances reach ±0.0005 inches, while turning processes can go down to ±0.0001 inches. This makes it ideal for components where even the smallest deviation could affect performance or safety.

Industries such as aerospace, medical devices, and automotive rely heavily on CNC machining. It’s commonly used to create landing gear parts, gearbox housings, surgical implants, and rapid prototypes.

Because of its high repeatability and fast setup changes, it’s also an efficient solution for short production runs and design iterations.

Another benefit of CNC machining is its integration with digital inspection tools. Real-time monitoring and feedback loops allow in-process adjustments to maintain dimensional accuracy.

This level of control is essential when you’re producing parts that need to pass strict quality standards.

Metal Casting

Metal casting is a precision manufacturing process where molten metal is poured into a mold and allowed to solidify into a specific shape.

Once cooled and ejected, the final piece reflects the internal geometry of the mold with high dimensional accuracy. It’s particularly effective for producing complex metal components at scale, especially when uniformity across a large batch is essential.

The process begins with the creation of a mold, which can be permanent or expendable, depending on the volume and complexity of the production run.

Common materials used in casting include aluminum A356, grey iron GG-25, and heat-resistant alloys such as Inconel 718.

These allow you to balance performance with manufacturability based on the application’s mechanical and thermal requirements.

One of the key advantages of metal casting is its suitability for high-volume production. A single mold can generate more than 10,000 identical components, making it a highly efficient method for mass production.

It also allows for thin-wall features, under 2 mm, and integrated structural supports that reduce the need for post-processing or assembly.

Metal casting is often used in the automotive industry for engine blocks, gear housings, and brake components. It’s also common in aerospace applications that require durable yet lightweight parts with consistent performance under stress.

Injection Molding

Injection molding is a high-efficiency process used to produce complex plastic components by injecting molten polymer into a precision-engineered mold cavity. This method is commonly applied in both prototyping and large-scale production runs where speed, surface finish, and repeatability are critical.

The process starts when a plastic resin, such as ABS, nylon, or polycarbonate, is heated until it reaches a molten state. It is then forced under high pressure into a mold that defines the final part shape.

After the material cools and solidifies, the mold opens, and the part is ejected. This entire cycle can take as little as five seconds, allowing you to manufacture millions of identical parts annually with minimal variation.

Injection molding supports tolerance windows as tight as ±0.05 mm, especially in multi-cavity molds where consistency across parts is vital. It also delivers smooth surface finishes with roughness values under 1 µm, reducing the need for downstream polishing or coating.

This process is widely used in industries such as consumer electronics, automotive interiors, and medical devices.

Applications include enclosures, fasteners, gears, and implantable components. Its compatibility with a broad range of plastics and composite materials adds flexibility to both functional and aesthetic designs.

Injection molding aligns well with precision manufacturing goals because it combines tight dimensional control with high throughput. You can incorporate complex internal features, precise wall thicknesses, and embedded elements, all while maintaining low per-unit cost at volume.

Laser Cutting

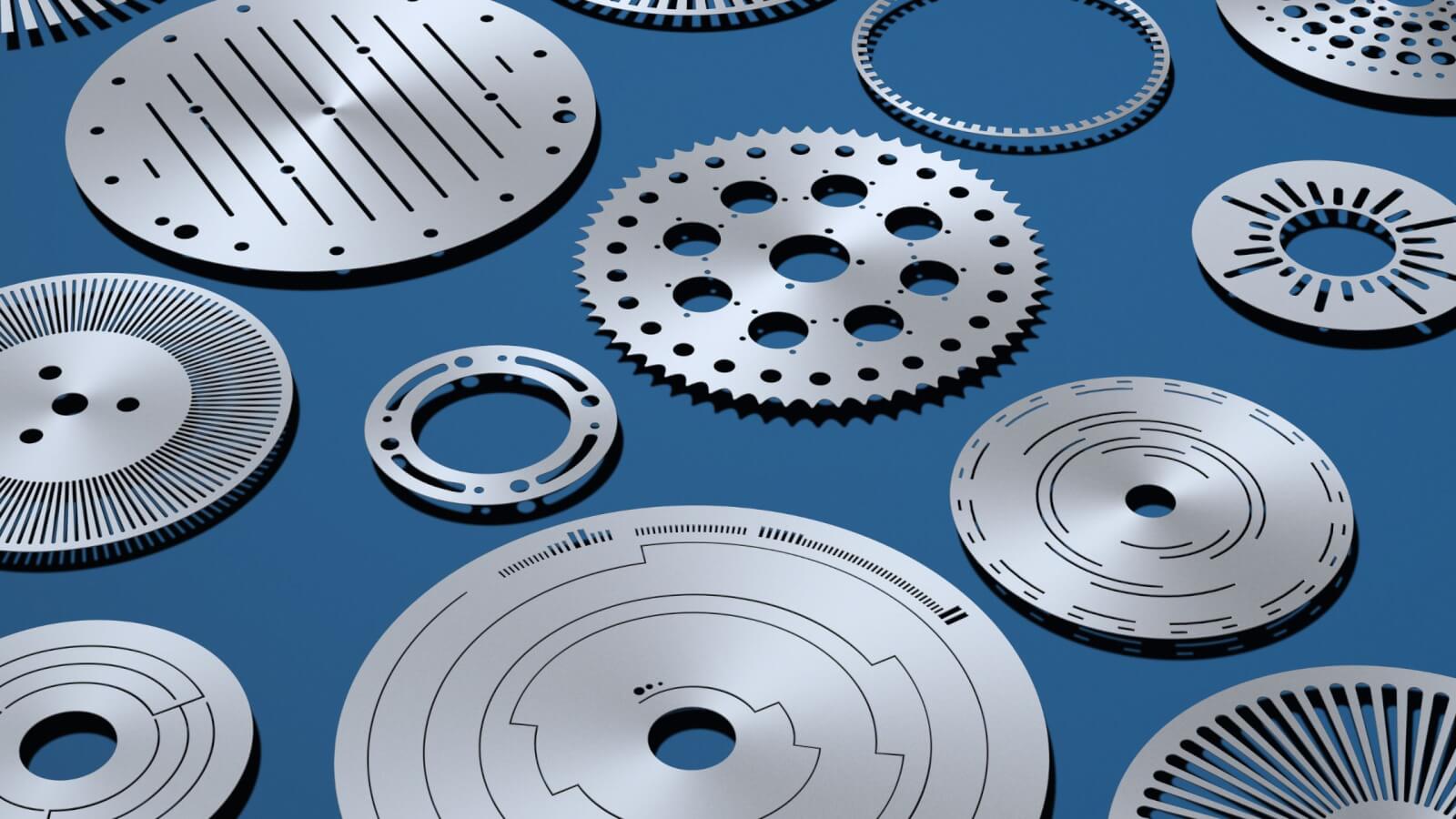

Laser cutting is a non-contact precision manufacturing method that uses concentrated light energy to cut through materials like metals, plastics, and composites. This process is widely used for creating complex geometries in parts where traditional machining may introduce too much variation, material waste, or thermal distortion.

The process begins by directing a high-powered laser beam, typically from a fiber-laser system, onto a specific area of the workpiece. The heat generated is intense enough to melt or vaporize the material instantly.

Assisted by gas jets, the molten material is removed, leaving behind a narrow and clean kerf. These kerfs can be less than 0.1 millimeters wide, allowing for highly intricate patterns, even in dense materials like stainless steel or tool steel.

One major benefit of laser cutting is its ability to deliver precise shapes with minimal material waste. It requires no physical tooling, which reduces setup time and cost. Since the beam is controlled digitally, you can switch between part designs quickly, which is ideal for custom jobs or rapid prototyping.

Laser cutting is often used in the electronics, aerospace, and medical industries for enclosures, brackets, and fine-detail components. For example, a fiber-laser can cut 3 mm stainless at speeds up to 30 meters per minute, significantly reducing lead times in sheet metal fabrication..

Additive Manufacturing / 3D Printing

Additive manufacturing, also known as 3D printing, builds parts layer by layer using digital design files. Unlike subtractive methods that remove material from a solid block, this process adds material only where needed, resulting in efficient use of resources and the ability to create intricate internal structures that would be impossible to machine conventionally.

The workflow starts with a 3D CAD model. That file is sliced into cross-sections, and each layer is printed sequentially using materials like polymers, resins, or metal powders. Laser-based methods such as laser powder bed fusion can achieve feature resolutions as small as 50 microns. This makes the process ideal for complex applications such as lattice structures, heat exchangers, or medical implants.

One of the most significant advantages is the speed of development. Since no tooling is required, you can go from concept to physical part in under 48 hours. This rapid iteration cycle supports product validation and reduces time to market.

In industrial settings, hybrid systems combine additive and subtractive capabilities in the same machine. These setups allow you to print a near-net-shape part and finish critical surfaces in one workflow, achieving surface roughness as low as Ra 3.2 microns.

Additive manufacturing supports a wide range of industries, including aerospace, automotive, and medical technology.

What Surface Finishing Techniques are Used in Precision Manufacturing?

Several finishing methods are commonly used depending on the material and the end-use of the part. These include polishing, anodizing, powder coating, and plating. Each technique improves specific performance characteristics while also refining how a part looks and feels.

- Polishing is used to smooth surfaces by removing tool marks or minor imperfections. It helps you achieve uniformity and reduce surface roughness, which is important for assemblies requiring low friction or fluid contact.

- Post-machining techniques like media tumbling can reduce edge radii to under 0.05 mm, which lowers stress concentrations and enhances fatigue strength.

- Anodizing, especially Type III hard-coat, adds a dense oxide layer to aluminum surfaces, improving wear resistance by over 25 microns while maintaining light weight. This is widely used in aerospace and electronics.

- Powder coating applies a durable, corrosion-resistant finish ideal for harsh environments. It also offers you a wide range of colors and textures, which is useful in consumer-facing products or machinery.

- Electroless nickel plating is another common option. It enhances corrosion resistance, often exceeding 1,000 hours in salt spray tests. This makes it suitable for parts exposed to moisture, chemicals, or temperature variations.

What Materials Are Commonly Used in Precision Manufacturing?

The main categories include metals, plastics, and composites. Each offers unique benefits depending on the part’s intended use and the manufacturing process applied. Metals provide strength and heat resistance, making them ideal for structural and load-bearing components. Plastics support complex geometries, fast production, and low weight, especially in prototyping and consumer products. Composites combine materials to achieve performance characteristics that would be difficult to obtain from a single base element.

Metals

Metals are among the most commonly used materials in precision manufacturing. They offer the strength, heat resistance, and machinability needed for tight-tolerance parts in demanding industries like aerospace, automotive, and medical.

Aluminum 6061-T6 is a lightweight alloy with a density of 2.70 g/cm³, often chosen for UAV frames and lightweight structures. It machines well and holds tight dimensional tolerances with minimal tool wear.

Stainless steel 316L is preferred for environments that require both corrosion resistance and mechanical integrity, maintaining a yield strength above 170 MPa at temperatures up to 400 °C.

This makes it a reliable option for medical tooling and high-temperature industrial parts.

Titanium Ti-6Al-4V stands out for its biocompatibility and weight advantages, it’s about 45 percent lighter than steel and ideal for surgical implants or aerospace brackets. Free-machining brass C360 is another important example, widely used for threaded connectors and fittings due to its ability to achieve smooth surface finishes down to Ra 0.8 µm with minimal cutting resistance..

Plastics

Plastics play a critical role in precision manufacturing, especially when weight reduction, electrical insulation, or cost efficiency is a priority. They are commonly used in medical devices, electronics housings, and rapid prototyping thanks to their versatility and ease of processing.

Acrylonitrile butadiene styrene (ABS) is valued for its toughness and impact strength of over 200 J/m. It’s frequently used for consumer and industrial enclosures due to its dimensional stability and ease of machining.

Polycarbonate (PC) offers high optical clarity, exceeding 88 percent, and includes a V-2 flame rating, making it suitable for transparent parts that require both safety and strength.

Nylon 6/6 is known for its low coefficient of friction, around 0.23, which makes it self-lubricating and ideal for applications like bushings and gears. PEEK is one of the most advanced plastics available, capable of continuous use at temperatures up to 250 °C. Its biocompatibility and chemical resistance make it suitable for implants such as spinal cages and for demanding aerospace components.

Composites and Advanced Materials

Composites and advanced materials are becoming increasingly essential in precision manufacturing, particularly in sectors like aerospace, defense, and electronics. These materials are engineered to provide performance characteristics that exceed what metals or plastics can offer individually, making them highly suitable for applications where strength-to-weight ratio, thermal stability, or specific resistance properties are critical.

Carbon-fiber-reinforced polymer (CFRP) is one of the most widely used composites in the aerospace industry. It offers a strength-to-weight ratio up to five times greater than steel, making it ideal for load-bearing structures such as aircraft spars, satellite panels, and drone frames.

Because CFRP can be layered and shaped with extreme precision, it fits well within processes that demand consistent geometries and minimal material waste.

Ceramic matrix composites are another example of high-performance materials used in advanced manufacturing. These materials can survive temperatures exceeding 1200 °C, making them ideal for turbine blades, exhaust systems, and heat shields in next-generation propulsion systems.

Their stability under extreme thermal and mechanical stress ensures reliable performance in applications where traditional materials would fail.

When combined with modern fabrication technologies like CNC machining and additive manufacturing, these materials enable new possibilities in precision part design. They support tight tolerance requirements, reduce weight, and extend operational life in high-demand environments.

What are the Core Benefits of Precision Manufacturing?

100vw, 1600px” data-lazy-src=”https://www.3erp.com/wp-content/uploads/2025/08/1.jpg” />Precision manufacturing advantages lie in dimensional accuracy, reduced waste, faster turnaround, consistent quality, and the ability to work with a broad range of materials and geometries. Whether you’re producing small batches or scaling to mass production, these benefits directly influence product performance, production efficiency, and cost savings.</p>

<ul>

<li><b>Improved Accuracy and Tighter Tolerance:</b> Precision processes consistently deliver parts with minimal dimensional deviation. This allows you to meet strict tolerance requirements that are critical in fields like aerospace, where even microns matter.</li>

<li><b>Faster Production Cycles:</b> Automated workflows and integrated CAD/CAM systems significantly reduce lead times. You can turn designs into parts in days instead of weeks, even for complex jobs.</li>

<li><b>Reduced Waste and Rework:</b> High repeatability means fewer rejected parts. Efficient material use cuts costs and supports sustainability goals</li>

<li><b>Greater Design Flexibility:</b> Advanced technologies allow for intricate geometries that traditional manufacturing can’t achieve, giving you more freedom in product design.</li>

<li><b>Consistency Across Volumes:</b> CNC machines and quality control systems ensure repeatability, even when producing thousands of identical parts.</li>

<li><b>Cost Efficiency Over Time:</b> Although initial setup costs may be higher, reduced errors, minimized rework, and shorter production cycles lead to long-term savings.</li>

<li><b>Broader Material Compatibility:</b> Precision methods handle everything from aluminum and titanium to engineering plastics and composites, giving you more options based on the application.</li>

</ul>

<h3 id=) Improved Accuracy and Tighter Tolerance

Improved Accuracy and Tighter Tolerance

Precision manufacturing stands out for its ability to achieve extremely high dimensional accuracy. By integrating computer-aided design, advanced CNC systems, and real-time feedback controls, you can maintain positional repeatability within ±2 microns. This level of control isn’t just theoretical, it has real-world implications for how your parts function in complex systems.

For example, in the aerospace industry, holding tight tolerances on fuel nozzles can increase combustion efficiency by up to 3 percent. The same applies across industries where small deviations can cause major performance issues. Whether you’re producing valve bodies, surgical tools, or sensor housings, maintaining consistency between pieces ensures parts fit, perform, and last as intended.

Faster Production Cycles

In today’s competitive landscape, turnaround time is often a deciding factor. Precision manufacturing helps you shorten production cycles without sacrificing quality. One of the main contributors to this speed is the direct connection between CAD modeling and CNC machine programming. As soon as your design is finalized, it can be converted into machining instructions and executed with minimal delay.

This streamlined flow cuts the typical design-to-part timeline significantly. What used to take four weeks using manual methods can now be accomplished in as little as three days with a high-mix CNC machining cell. That kind of agility allows you to respond quickly to customer demands, prototype faster, and bring new products to market ahead of your competitors.

Lower Manufacturing Costs

Precision manufacturing offers long-term cost advantages by reducing waste, rework, and manual intervention. Even though the initial setup for CNC machining or advanced automation may seem expensive, the efficiency gains over time lead to significant savings.

One example comes from a recent consumer electronics program, where implementing automated precision processes and minimizing scrap led to a 25% reduction in total manufacturing costs.

That kind of impact is possible because precise programming, tight tolerances, and accurate repeatability limit material overuse and eliminate trial-and-error production.

You also reduce labor costs by automating tasks that traditionally required skilled operators. With well-maintained machines and real-time quality control systems, each piece you produce gets closer to perfect on the first try.

Fewer failed parts mean lower inspection and return rates, which also cuts costs across your operations. Over time, this consistency supports stable pricing and strengthens your ability to compete in cost-sensitive markets.

Easier Prototyping and Testing

One of the major benefits of precision manufacturing is how easily it supports rapid prototyping and iterative testing. When you’re working with new product designs or complex components, the ability to produce and evaluate multiple design versions quickly is critical to development success.

Modern CNC machining services and digital fabrication technologies allow you to turn a CAD model into a high-quality prototype in just days. In fact, teams can test five to ten different designs per week, something that would have taken weeks or months using manual techniques.

This short feedback loop helps you validate fit, performance, and tolerances early in the design process.

By catching design flaws before mass production, you avoid costly downstream adjustments and delays. Plus, because the prototype parts are made with the same accuracy as final production parts, you’re testing real-world performance under actual conditions.

Compatibility with a Wide Range of Materials

Precision manufacturing stands out for its ability to handle a wide variety of materials without sacrificing dimensional integrity. Whether you’re working with high-strength metals like titanium or aluminum, engineering plastics like PEEK, or even composite materials, these processes give you the flexibility to design with performance in mind.

This material compatibility is especially valuable when you’re building multi-material assemblies or choosing specific properties such as chemical resistance, weight reduction, or conductivity. It allows you to match the right material to each component based on functional requirements, while still maintaining tight tolerances and consistent quality.

From stainless steel components in surgical instruments to polymer gears in robotics, the same precision manufacturing systems adapt to different materials with minimal adjustment. That saves you setup time, reduces tooling costs, and improves overall production efficiency.

Greater Consistency and Repeatability

Consistency is one of the strongest features of precision manufacturing. Once your process is dialed in, you can produce hundreds or thousands of identical parts with minimal variation. This level of repeatability is essential for high-volume production where any defect or dimensional drift can disrupt downstream assembly or field performance.

Data from statistical process control (SPC) systems show that high-performing precision lines can achieve a process capability index (Cpk) greater than 2.0. That means nearly all parts fall within the specified tolerance range, minimizing inspection effort and maximizing yield.

Repeatability also supports better inventory control and lean manufacturing goals. When you can trust that each part meets its exact specifications, you’re less likely to overproduce to compensate for quality issues. The result is reduced waste, lower inventory holding costs, and a stronger reputation for reliability in the marketplace.

Reduced Material Waste

One of the less visible but highly valuable benefits of precision manufacturing is the significant reduction in material waste. When you’re working with high-cost metals or specialty polymers, every gram matters, not just for cost, but also for environmental sustainability.

Because processes like CNC machining and additive manufacturing are tightly controlled by software, you can achieve precise cuts, optimized geometries, and near-net shapes with minimal excess. Tool-path optimization alone can reduce material usage by up to 15% per part, which adds up quickly in large production runs.

Less waste also means fewer raw material purchases and less scrap disposal, helping you stay within both budget constraints and sustainability goals.

Enhanced Safety and Fewer Human Errors

Precision manufacturing reduces operator risk and limits the chance of costly mistakes. By integrating automation, sensors, and software-driven controls, you minimize hands-on tasks that traditionally exposed workers to sharp tools, moving machinery, and hazardous materials.

In light-out machining environments, where machines run autonomously with minimal supervision, operator exposure to chips, coolants, and repetitive tasks drops by more than 80%. That’s a major safety improvement, especially in operations running around the clock.

At the same time, removing human variability from the process reduces errors that might otherwise affect tolerances, material alignment, or tool calibration. With machines making continuous adjustments and monitoring data in real time, the system catches deviations before they become defects, supporting higher quality control and workplace safety in a single step.

Scalability for Mass Production

As demand grows, so should your production capabilities, and this is where precision manufacturing truly proves its value. These systems are built to scale, whether you need ten parts or ten thousand. Once a part is fully programmed and validated, it can be replicated consistently without rework or manual adjustment.

High-rigidity horizontal machining centers, for example, routinely maintain overall equipment effectiveness (OEE) levels above 85% during 24/7 production. That means more uptime, fewer interruptions, and a higher output per machine.

This scalability allows manufacturers across industries to ramp up production while maintaining consistent specifications and tolerances. Whether you’re producing stainless steel brackets, plastic housings, or complex medical components, precision processes give you the confidence that every part, regardless of volume, will meet the same exacting standards.

What are the Common Challenges in Precision Manufacturing?

100vw, 1600px” data-lazy-src=”https://www.3erp.com/wp-content/uploads/2025/08/2.jpg” />Although precision manufacturing brings substantial advantages, it also comes with specific limitations that can affect your production strategy. The top challenges most manufacturers face are high initial investment, skilled labor shortages, and increased maintenance demands when scaling operations.</p>

<h3 id=) High Initial Investment

High Initial Investment

If you’re planning to set up or upgrade a facility with high-end equipment, be prepared to invest significantly up front. A single 5-axis CNC machining center can exceed $500,000 before factoring in tooling, software, and integration.

These machines, along with advanced quality control systems and automation platforms, form the backbone of modern precision processes. But the initial capital outlay can put pressure on small to mid-sized manufacturers with limited budgets.

The long-term value is real, precision equipment reduces scrap, increases throughput, and enables new product capabilities. However, to realize those gains, you need a strong production plan and steady demand to justify the up-front spend..

Skilled Labor Shortages

Even with the most advanced machines and software, you still need experienced people to operate, program, and maintain them. And that’s becoming a major challenge. Globally, the manufacturing sector is facing a projected shortage of 2 million skilled workers by 2030.

Precision machining requires more than just basic machine operation. You need engineers who understand CAD/CAM systems, technicians trained in interpreting SPC data, and programmers capable of writing efficient toolpaths. Without this knowledge, even the best equipment won’t perform to its potential.

If you’re considering scaling your operations or transitioning into more advanced manufacturing methods, investing in workforce development is essential. Upskilling current employees and partnering with technical schools or training programs can help bridge the gap. Without addressing the labor shortage, you risk bottlenecks that delay production, reduce accuracy, and increase downtime.

Machine Downtime and Maintenance

Machine downtime in precision manufacturing isn’t just a disruption, it’s a threat to accuracy, lead times, and overall throughput. When you’re working with equipment designed to meet sub-micron tolerance requirements, any mechanical deviation can quickly result in dimensional drift or surface finish defects.

Keeping these machines in optimal condition demands regular maintenance and proactive monitoring. High-rigidity CNC machining centers, for example, rely on tight thermal control and precise spindle alignment. Over time, continuous operation increases wear on critical parts like tool holders, linear guides, and servo drives. This impacts repeatability and may increase the risk of errors mid-production.

To prevent unscheduled downtime, manufacturers are turning to predictive maintenance systems that use real-time sensor data to detect anomalies in vibration, temperature, or load. This approach allows you to intervene early, before a minor issue becomes a costly repair.

Tight Tolerances and Error Margins

Tight tolerances are what make precision manufacturing so powerful, but they also introduce higher risks for dimensional failure. When you’re aiming for tolerances as fine as ±2 microns, even a slight calibration shift or tool wear can push a component out of spec.

Maintaining this level of accuracy over extended production runs requires continuous quality control and strict process stability. You need to account for thermal expansion, machine rigidity, and material behavior under cutting forces. Precision machining setups often use in-process probes and closed-loop feedback systems to monitor these variables in real time.

But even with advanced tools, achieving flawless repeatability requires vigilance. A minor programming error or misaligned fixture can introduce costly deviations. That’s why your quality control measures need to start from the design phase and carry through to final inspection.

Regulatory and Industry Compliance

Precision manufacturing doesn’t just demand technical accuracy—it requires strict adherence to industry regulations and global quality standards. Whether you’re supplying components to the aerospace industry, medical sector, or defense contractors, you’ll need to navigate a maze of documentation, audits, and third-party certifications.

Compliance involves more than just meeting dimensional specs. It includes tracking traceability data, maintaining process documentation, and proving that your quality control systems are both effective and validated. This level of oversight is especially important when you’re working with safety-critical parts like implants or flight hardware.

Most precision manufacturers align their processes with ISO 9001 or industry-specific frameworks like AS9100 or ISO 13485. These systems create a structured approach to production, documentation, and continuous improvement. But meeting these standards adds layers of administrative responsibility, and you’ll need trained staff, updated procedures, and regular internal audits to keep up.

How to Ensure Precision in Manufacturing Processes?

To meet tight tolerance requirements and maintain repeatability, manufacturers must apply structured practices at every stage of the production process. From software programming to hardware calibration, your choices directly affect accuracy, cost, and long-term equipment reliability.

Key strategies include regular calibration of equipment, integration of computer-aided design and manufacturing software, and strict quality control measures during production. These methods not only improve part consistency but also reduce material waste and human error.

To maintain the highest level of precision, many companies adopt a layered approach that combines digital automation with skilled labor oversight. This helps you preserve component integrity while accelerating turnaround times, especially in high-mix, low-volume environments where flexibility is critical.

Regular Equipment Calibration

Precision manufacturing begins with machine stability. If your equipment isn’t calibrated regularly, even the most advanced CNC machining centers can drift from their specifications. This creates alignment issues that compound over time, especially in mass production environments.

Routine calibration ensures your machines stay within defined tolerance bands. This includes inspecting linear guides, checking spindle runout, and re-aligning tool changers. It’s not just about compliance, it’s about confidence in your process.

By scheduling proactive calibration intervals, you reduce measurement uncertainty and extend the lifespan of your machinery. Most precision manufacturers integrate calibration data into their quality control systems to detect deviations before they affect production.

Advanced Program Utilization (CAD/CAM)

In modern precision manufacturing, software precision is just as vital as hardware accuracy. Computer-aided design (CAD) and computer-aided manufacturing (CAM) systems translate your product concept into exact tool paths and material instructions. When programmed correctly, these systems eliminate variability caused by human error and reduce costly mistakes during production.

CAD platforms allow engineers to define precise geometries, including tolerances, surface textures, and assembly interfaces. CAM tools then generate optimal tool paths based on this data, often simulating thermal expansion or tool wear ahead of time.

Advanced CAM systems also support toolpath optimization and in-process metrology, which further increases production reliability. This level of control enables you to take full advantage of the capabilities of CNC milling machines, especially in industries like aerospace or medical devices where every micron counts.

Continuous Training and Workforce Education

People are the foundation of any successful manufacturing process. Even with advanced CNC machining and computer programming, you can’t achieve high precision if your team lacks the right knowledge.

Continuous training helps machine operators, programmers, and quality engineers stay aligned with evolving technologies and tighter production standards.

Effective training programs should include hands-on exposure to equipment, CAD/CAM software updates, and refresher courses on quality control measures. This reduces human error and improves your production system’s resilience to variability.

Many manufacturers report a measurable drop in scrap rates and setup times after investing in upskilling initiatives.

Quality Control Integration from Start to Finish

Precision isn’t something you check at the end, it’s something you build into every phase of production. Leading manufacturers integrate quality control from initial CAD design through final assembly and packaging. This approach ensures that each piece meets both technical specifications and performance requirements.

Key steps include in-process inspections, statistical process control (SPC), and automated metrology systems. These allow you to catch deviations early and adjust tooling or parameters before defective parts accumulate.

When quality control is treated as a continuous feedback loop rather than a final checkpoint, you lower the risk of errors, reduce material waste, and improve yield rates—even in high-mix, low-volume production runs.

Material Selection and Handling Considerations

Precision starts with your choice of materials. Whether you’re working with stainless steel, aluminum, tool steel, or high-performance polymers, selecting the right material affects machinability, tolerance stability, and final product reliability. Improper handling, on the other hand, can compromise everything.

You should always factor in material properties like thermal expansion, hardness, and surface finish requirements. Some composites and advanced alloys need controlled storage environments or specific fixturing methods to maintain dimensional stability during processing.

Consistent handling, especially during loading, unloading, and staging, helps prevent warping, contamination, or unintentional surface damage.

Investment in the Latest Technology

Modern CNC machines, automated inspection systems, and digital twins give you the tools to meet tighter tolerance requirements, especially in demanding sectors like aerospace and medical devices.

High-end equipment improves repeatability and supports complex geometries that traditional machines can’t handle. For example, five-axis CNC milling centers paired with adaptive software enable real-time toolpath optimization, which directly improves efficiency and surface finish.

By adopting newer machinery, you’re not just upgrading your shop floor—you’re boosting your precision capabilities, shortening turnaround times, and future-proofing your production process in a competitive global market.

Monitoring Circuit Technologies (where applicable)

In some manufacturing fields, especially electronics, defense, and instrumentation, monitoring circuit technologies play a key role in ensuring precision. These integrated systems track electrical parameters like resistance, current, and voltage to maintain control over the manufacturing environment or embedded device behavior.

When used alongside advanced production controls, these technologies help catch deviations early in the process. This reduces the likelihood of defects, especially in small-run or high-stakes production where failure isn’t an option.

Incorporating monitoring circuits is one way precision manufacturers extend their quality control measures from physical parts to embedded systems. It gives you tighter oversight, particularly in applications where digital functionality and mechanical accuracy must work hand-in-hand.

Predictive Maintenance Practices

Downtime is the enemy of efficiency, especially when you’re running high-volume or continuous operations. Predictive maintenance helps you avoid unexpected breakdowns by using real-time data and sensor feedback to forecast equipment wear before it becomes a problem.

Precision manufacturing relies on high-performance machinery like CNC machining centers, EDM systems, and laser cutters. These machines require tight calibration and consistent upkeep. Predictive systems use vibration analysis, thermal imaging, and cycle count metrics to tell you when a component is likely to fail.

By acting before failure, you reduce unplanned downtime, extend machine life, and sustain your production accuracy without costly interruptions.

What Types of Parts Are Best Suited for Precision Techniques?

Precision manufacturing is best suited for components that demand extreme accuracy, high repeatability, and minimal margin for error. These typically include parts with complex geometries or micro-scale features where even a few microns can impact performance or safety. Any device requiring tolerances of ±10 µm or tighter stands to benefit significantly from precision machining processes.

Precision manufacturing is best suited for components that demand extreme accuracy, high repeatability, and minimal margin for error. These typically include parts with complex geometries or micro-scale features where even a few microns can impact performance or safety. Any device requiring tolerances of ±10 µm or tighter stands to benefit significantly from precision machining processes.

These parts often serve critical functions in medical devices, aerospace mechanisms, and high-performance electronics. You’ll find that precision engineering is essential when designing products where the slightest deviation could lead to failure or inefficiency.

Some of the most common candidates include:

- Miniature valves used in fluid regulation systems

- Orthopaedic screws for surgical implants

- Turbine blades for jet engines and energy generation

- Camera lens mounts requiring stable alignment

- Micro-fluidic chips in diagnostic devices

What Industries Rely on Precision Manufacturing?

Whether you’re designing for space exploration or consumer wearables, precision manufacturing processes help reduce human error, maintain tolerance requirements, and enable innovation at scale.

Industries that heavily rely on these capabilities include:

- Aerospace, where turbine blades, fuel nozzles, and structural brackets must meet exacting standards

- Medical, for implants, surgical tools, and micro-sized device housings

- Automotive, especially in engine blocks, transmission parts, and safety-critical systems

- Consumer electronics, where high-density, miniaturized components are standard

- Defense and optics, where failure is not an option

Aerospace

The aerospace industry is arguably one of the most demanding environments for precision manufacturing. Aircraft and spacecraft components must adhere to the strictest specifications due to the extreme operational pressures, temperatures, and speeds involved. Any deviation from tolerance can have catastrophic consequences.

CNC machining, advanced casting, and additive manufacturing are commonly used to produce parts such as turbine blades, actuator housings, heat shields, and control surfaces. These components often require exotic materials like titanium alloys and Inconel due to their strength-to-weight ratios and thermal resistance.

To ensure compliance, aerospace manufacturers implement extensive quality control measures and documentation protocols. The goal is clear: keep every part within its precise specifications to ensure safety, fuel efficiency, and reliability across thousands of flight hours.

Automotive

In the automotive industry, precision manufacturing enables the production of high-performance components such as transmission casings, fuel-injection parts, and gear assemblies. These components must meet strict dimensional accuracy to function reliably under constant pressure and wear.

Modern cnc machining systems are used to fabricate parts with consistent geometry, ensuring tight fits and smooth motion. This level of accuracy also supports lower emissions and improved fuel efficiency, two top priorities in automotive design.

You’ll also see precision machining used in prototype development, where engineers validate new ideas rapidly before scaling into mass production. For manufacturers, this precision translates into cost savings, reliability, and long-term vehicle performance.

Medical Devices

Medical device manufacturing demands unmatched accuracy. From orthopedic implants to surgical instruments, every component must comply with tight tolerance requirements and strict regulatory standards. A single micron-level deviation could compromise a device’s safety or functionality.

That’s where precision manufacturing excels. Whether you’re producing spinal cages, dental tools, or miniature pumps, processes like CNC milling and multi-axis machining deliver repeatable results with traceable quality control measures. Titanium, stainless steel, and biocompatible polymers are often used for their strength and safety.

Electronics

Precision manufacturing is the backbone of modern electronics. With the demand for smaller, faster, and more reliable devices, manufacturers must meet extreme tolerance specifications, often down to the micron level.

From smartphone housings to microfluidic sensor casings and lens holders, every feature must align perfectly. Materials like plastics, aluminum, and composites are processed with tight control to minimize waste and ensure proper assembly fit.

Consumer Goods

In the consumer goods industry, precision manufacturing is critical to ensuring consistent product quality, tight fitment, and long-term durability.

Whether you’re producing electric toothbrush housings, smartphone casings, or razor components, these products rely on exact specifications and flawless surface finishes to meet customer expectations.

CNC machining and high-tolerance injection molding allow manufacturers to produce intricate geometries and snap-fit assemblies with repeatable results.

Dimensional control also supports multi-part assembly workflows by ensuring seamless part compatibility straight off the line.

With reduced error rates, minimal waste, and the ability to scale production efficiently, precision techniques offer a major advantage in a market driven by design, performance, and speed to market.

Robotics

Robotics demands a high level of mechanical and electronic integration, where the reliability of every component directly affects system performance. Precision manufacturing enables you to build robotic joints, housings, arms, and end-effectors that perform under constant load without deviation.

Tolerances in these systems often fall below ±10 µm, and cnc milling plays a vital role in creating components like gearboxes and control linkages with exacting standards. By using advanced materials such as tool steel or aluminum alloys, manufacturers ensure strength-to-weight efficiency and corrosion resistance.

Defense and Military

The defense industry relies on precision manufacturing to deliver mission-critical systems that function flawlessly under extreme conditions. Applications include components for weapon systems, surveillance technologies, and aerospace-grade targeting platforms, all requiring zero tolerance for error.

CNC machining, additive manufacturing, and advanced inspection tools are commonly used to achieve the tight dimensional control needed in this sector. For instance, radar housing brackets or missile fins may demand positional accuracies within microns to maintain operational safety and effectiveness.

Precision processes support not only reliability and performance, but also traceability and compliance with military-grade quality control measures, essential for national security and high-risk applications.

How is Quality Control Managed in Precision Manufacturing?

100vw, 1600px” data-lazy-src=”https://www.3erp.com/wp-content/uploads/2025/08/6.jpg” />Companies rely on a mix of digital tools and real-time monitoring techniques to track compliance. These include vision systems, surface scanners, coordinate measuring machines, and in-line sensors. Each device helps confirm part specifications without disrupting flow. Statistical process control (SPC) and error-proofing routines are often implemented on CNC machining centers to detect drift or wear before it causes scrap.</p>

<p>By applying rigorous quality control measures across every phase, from raw material verification to final inspection, you can reduce downtime, improve efficiency, and meet the exact specifications your customers expect. It’s what allows precision manufacturers to stay competitive and trusted in high-stakes sectors.</p>

<h3 id=) Measurement Techniques: Accuracy, Precision, and Tolerance

Measurement Techniques: Accuracy, Precision, and Tolerance

To maintain quality across production runs, you need to control three key metrics: accuracy, precision, and tolerance. Although they’re related, each serves a specific role in defining how well your parts perform.

Accuracy refers to how close a measurement is to the intended target. Precision describes the repeatability of that measurement across multiple trials. Tolerance defines the allowed deviation from the target dimension. These concepts directly influence cost, fit, and overall product reliability.

For example, a metal connector specified at 10.00 mm ±0.01 mm must stay within a narrow band of 9.99 to 10.01 mm. Aerospace or medical applications often demand even tighter tolerances, sometimes below ±5 microns. That level of control requires advanced tooling, stable machines, and strict process discipline.

Inspection Methods

To keep accuracy high and error rates low, advanced metrology tools are integrated across every stage of the manufacturing process.

Coordinate measuring machines (CMMs) are a foundational tool. These machines use tactile probes or lasers to map part geometries against CAD models, offering micron-level dimensional feedback. In high-throughput settings, laser scanners capture 3D surface profiles in real time, detecting irregularities without contact. Digital micrometers, calipers, and bore gauges also provide reliable manual checks for critical features such as thread depth, bore size, and wall thickness.

Each of these tools supports the high tolerance requirements typical in industries like aerospace and medical device production. Their proper use ensures that finished parts stay within acceptable variation limits, improving product performance, safety, and repeatability in mass production environments.

Standards and Compliance

Precision manufacturing depends on rigorous adherence to global standards and regulations. You can’t just meet internal goals, you need documented, verifiable compliance to assure customers and industries that every part meets safety and functionality benchmarks.

International standards like ISO 9001 and ISO 13485 form the backbone of most quality control systems. These frameworks ensure that your processes, from material selection to final inspection, are properly documented, controlled, and audited. In aerospace, compliance with AS9100 is often required, while medical manufacturers may need FDA or CE certifications tied to traceability and cleanliness.

These standards help reduce human error, support reliable component interchangeability, and enforce structured quality control measures throughout the production cycle.

What Role Do ERP Systems Play in Precision Manufacturing?

ERP (Enterprise Resource Planning) systems serve as centralized platforms that streamline every aspect of the manufacturing process, from planning and inventory to shop floor execution.

By integrating real-time data from machines, people, and materials, ERP tools help you coordinate CNC machining operations, reduce human error, and align output with customer specifications.

These systems support resource allocation, enable predictive scheduling, and provide visibility into cost drivers.

In industries with strict tolerance requirements, having synchronized data across departments helps ensure that every precision part meets dimensional and performance standards.

ERP software also facilitates documentation for regulatory compliance and tracks quality control measures throughout production, offering valuable insights that improve repeatability and reduce waste.

SAP Business One

SAP Business One offers a robust solution for precision-focused companies that need to balance efficiency with traceability. Its real-time integration with supply chain, inventory, and production modules helps you manage tooling, raw materials, and machine availability in a unified platform.

What makes it especially suited for precision manufacturing is its ability to align customer requirements with production parameters. You can define tolerances and quality control checkpoints directly within job orders.

For companies producing components for the aerospace industry or complex medical devices, this ensures alignment with design specifications and regulatory standards. SAP also supports batch-level tracking, document version control, and cost accounting, all vital in maintaining part consistency across multiple production runs.

Acumatica

Acumatica is a cloud-based ERP solution tailored for modern manufacturers aiming to scale their operations while maintaining high accuracy and speed. It excels in environments where flexibility, integration, and cost visibility are essential, such as precision machining and multi-axis CNC milling operations.

The system helps you track job performance, material usage, and quality control measures in real time. With embedded analytics and support for CAD integration, Acumatica bridges the gap between design and production, reducing errors caused by miscommunication.

For manufacturers focused on custom parts or high-mix, low-volume runs, Acumatica allows for dynamic routing, adaptive scheduling, and quick feedback loops, all of which support better decision-making and faster turnaround without compromising on quality.

How Does Precision Manufacturing Compare to Traditional Manufacturing?

Traditional methods like casting, manual milling, or stamping rely heavily on operator skill and basic machines. These approaches are more forgiving in terms of tolerance, often acceptable within ±0.5 mm. They’re typically suited for high-volume, low-cost parts where extreme accuracy isn’t critical.

On the other hand, precision manufacturing uses advanced tools like CNC machining and CAD-driven processes to meet much tighter tolerance requirements—often within ±0.01 mm or even finer. This accuracy is essential in industries like aerospace or medical implants, where part misalignment could cause failure.

You’ll see the difference in cost as well. A basic die-cast mold might cost $3,000–$5,000 to produce, while a precision-milled mold with tight tolerances could exceed $20,000.

However, the benefits of precision include fewer defects, better part fit, and lower waste, which over time, can lead to cost savings, especially in mass production.

As a result, manufacturers who prioritize quality control, performance, and reliability often shift toward precision machining despite the higher initial investment. This approach delivers measurable advantages in both repeatability and overall production efficiency.

Comparison Table – Precision vs. Traditional Manufacturing

| Factor | Traditional Manufacturing | Precision Manufacturing |

| Accuracy | ±0.5 mm | ±0.01 mm or less |

| Machines Used | Manual mills, casting equipment | CNC machining, 5-axis mills |

| Tolerances | Broad | Tight (micron-level) |

| Human Error Impact | High | Low (automation and programming) |

| Material Use | Higher waste | Optimized with toolpaths |

| Cost of Tooling | $3,000–$5,000 | $15,000–$25,000 |

| Setup and Turnaround | Slower | Faster with CAD/CAM systems |

| Applications | General consumer products | Aerospace, medical, optics, robotics |

Is Precision Manufacturing Expensive?

Precision manufacturing is often perceived as costly, but the answer depends on how you measure long-term value. Upfront, it does require a greater investment in machines, tooling, and skilled labor. But when you’re aiming for accuracy, repeatability, and reduced rework, those costs are often justified.

Initial capital expenses are the largest factor.

A standard 3-axis CNC machine might cost $70,000, while a high-precision 5-axis system can exceed $500,000. Tooling and fixturing tailored for tight tolerance components can range from $2,000 to $20,000 per setup. Add metrology equipment, such as CMMs, and you’re looking at another $30,000 to $100,000.

Labor costs also rise due to the need for experienced programmers and operators familiar with CAD/CAM systems and tolerance requirements. However, the precision process minimizes waste, speeds up turnaround, and often offsets capital expenses within 18 to 24 months.

You’re not just paying for machines; you’re investing in quality control, reduced human error, and lower scrap rates.

When you consider the reduced need for rework, less material waste, and superior product performance, the benefits of precision begin to outweigh the initial costs, especially in high-value sectors like aerospace or medical device manufacturing.

What Design Factors Should Be Considered in Precision Manufacturing?

Success starts with strong CAD modeling and a design approach that respects the constraints and strengths of CNC machining, EDM, or additive tooling.

One of the most important principles is Design for Manufacturability (DFM). It ensures your part can be made efficiently without sacrificing function.

You’ll want to avoid overly complex shapes or features that are difficult to reach with cutting tools.

Simple, consistent geometries reduce error rates and machine time.

Clear tolerance specifications are also essential. Over-tightening tolerances can increase cost without adding value.

For instance, calling for ±5 µm on a non-critical feature may require more advanced machines and metrology than necessary. Always balance tolerance requirements with function.

CAD models should also reflect the final production intent. You should use computer-aided design tools that support simulation and analysis. This lets you test fit, stress, and thermal behaviors before you cut a single piece of material.

How Does Precision Manufacturing Support Environmental Sustainability?

Toolpath optimization, for example, can lower scrap rates and maximize raw material usage. This is especially impactful when working with expensive materials like titanium or stainless steel. Some manufacturers now reclaim over 95% of titanium chips for remelting, a key move in circular-economy practices.

Energy efficiency also improves through the use of advanced machinery.

High-efficiency spindles and intelligent power management systems can reduce energy consumption per machined part by up to 10%. When applied at scale, that’s a huge reduction in your facility’s carbon footprint.

Lean manufacturing principles further reduce environmental impact by streamlining workflows, minimizing excess inventory, and cutting down unnecessary movement and operations. These improvements aren’t just about sustainability, they also reduce operating costs and increase throughput.

What are Some Common Problems and Defects with Precision Manufacturing?

There are at least five key defects you should be aware of when working with tight tolerance requirements. Each issue below includes a short explanation and practical advice to help you identify and avoid them:

- Burrs: Burrs are small, unwanted projections of material left on part edges. They’re typically caused by dull tooling or excessive feed rates in CNC machining. To prevent burrs, use sharp tools, proper chip load, and deburring routines in your finishing operations.

- Tool Chatter: This vibration between tool and workpiece leaves wave-like marks on surfaces. It’s often due to poor tool holding or unstable fixturing. Using high-rigidity tool holders, balanced cutters, and shorter tool overhangs can reduce chatter significantly.

- Thermal Distortion: Changes in machine temperature can shift critical dimensions mid-process. Thermal drift is especially problematic for long or complex components. The solution? Maintain a thermally stable environment, ideally within ±1 °C and preheat materials and machines when necessary.

- Dimensional Drift: Over long runs, small shifts in calibration or tool wear can cause cumulative inaccuracy. Periodic recalibration of machines and in-process quality control checks help catch issues before parts deviate from specs.

- Surface Tearing: Poor finishes and torn surfaces often result from inadequate coolant or improper speeds and feeds. Correct this by adjusting coolant flow, reviewing cutting parameters, and optimizing tool paths for the material used.

How Can You Choose the Right Precision Manufacturing Partner?

You should evaluate a potential manufacturer based on at least five major criteria: capabilities, certifications, equipment, experience, and quality control measures.

Start by reviewing their range of services. Can they handle both CNC milling and turning? Do they have in-house quality inspection tools like CMMs or XRF analyzers? These capabilities reflect their readiness to handle complex production runs.

Also look at certifications. ISO 9001 and ISO 13485 are critical if you’re in regulated industries like aerospace or medical devices. Ask about their Cp/Cpk process capability data and Overall Equipment Effectiveness (OEE) averages to assess consistency.

Digital platforms now allow you to upload files such as STEP, IGES, and DXF for real-time quoting, saving time in the sourcing process.

3ERP delivers professional service tailored for precision part buyers. With years of experience, we support clients with deep technical knowledge and fast quoting. They offer tolerances as tight as ±0.01mm, supported by ISO 9001:2015 certification.

Our factory includes CNC milling, turning, EDM, and wire EDM machines, all monitored using Hexagon CMMs and Olympus XRF systems. This end-to-end control ensures every part meets exact standards, fast, efficient, and reliable.

Conclusion

Precision manufacturing isn’t just a technical process, it’s how we turn bold ideas into real, high-performing products that actually work in the real world. Whether you’re building something as complex as a jet engine or as compact as a smartwatch, the difference comes down to accuracy, repeatability, and smart design choices.

By using tools like CNC machining and computer-aided design, we can hit tight tolerances, cut down on waste, and still keep up with the speed and scale of modern production.

It’s not about choosing between quality and efficiency anymore, you can (and should) have both.

If you’re aiming to build products that meet high standards without blowing the budget, precision manufacturing gives you the control and confidence to do just that. It’s how we move faster, build smarter, and bring your ideas to life, one perfectly made part at a time.

Frequently Asked Questions

Can Precision Manufacturing Reduce Overall Production Costs?

Yes, precision manufacturing can significantly lower your total cost of production. Although upfront investments in CNC machines, tooling, and inspection systems can be high, the long-term cost savings are real. By reducing scrap rates, rework, and assembly failures, precision machining helps you control material costs and labor hours.

Is Precision Manufacturing Suitable for Prototyping?

Absolutely. Precision manufacturing is ideal for prototyping, especially when your design requires tight tolerances and functional accuracy. Processes like CNC milling and turning allow you to create test parts that mirror final production conditions. This lets you validate form, fit, and function without waiting weeks or using makeshift tools.